Liquid Ring Vacuum Pumps

●Feature

1.Suitable for vacuum extraction of moisture, vapors, condensable gases and particulates.

2.The compressed heat was absorbed by sealed fluid, equivalent to isothermal compressing, thus cause lower temperature of discharged gases and ensured high safety for explosible gases.

3.Due to no metal friction in internal, thus no lubricant is needed; totally pollution free and low maintenance cost.

4.An additional atmospheric device (air ejector) is installed at the intake port, the ultimate vacuum can reach to 6~2Torr; series connected with a mechanical booster pump can conserve energy and increase several times of pumping volume and ultimate vacuum.

5.A noise-free, gas liquid separator can be installed at the exhaust port.

●Applications

Vacuum forming, vacuum vulcanizing, vacuum drying, vacuum deaerating, vacuum casting, vacuum concentrating, vacuum extracting, vacuum impregnating, vacuum packaging, vacuum filling, vacuum transporting, vacuum filtering, sucking disk moving, paper-making dehydration, vacuum sterilizing, vacuum medical system, absorption process, fiber condensation, pressing machine air discharging.

●How it works

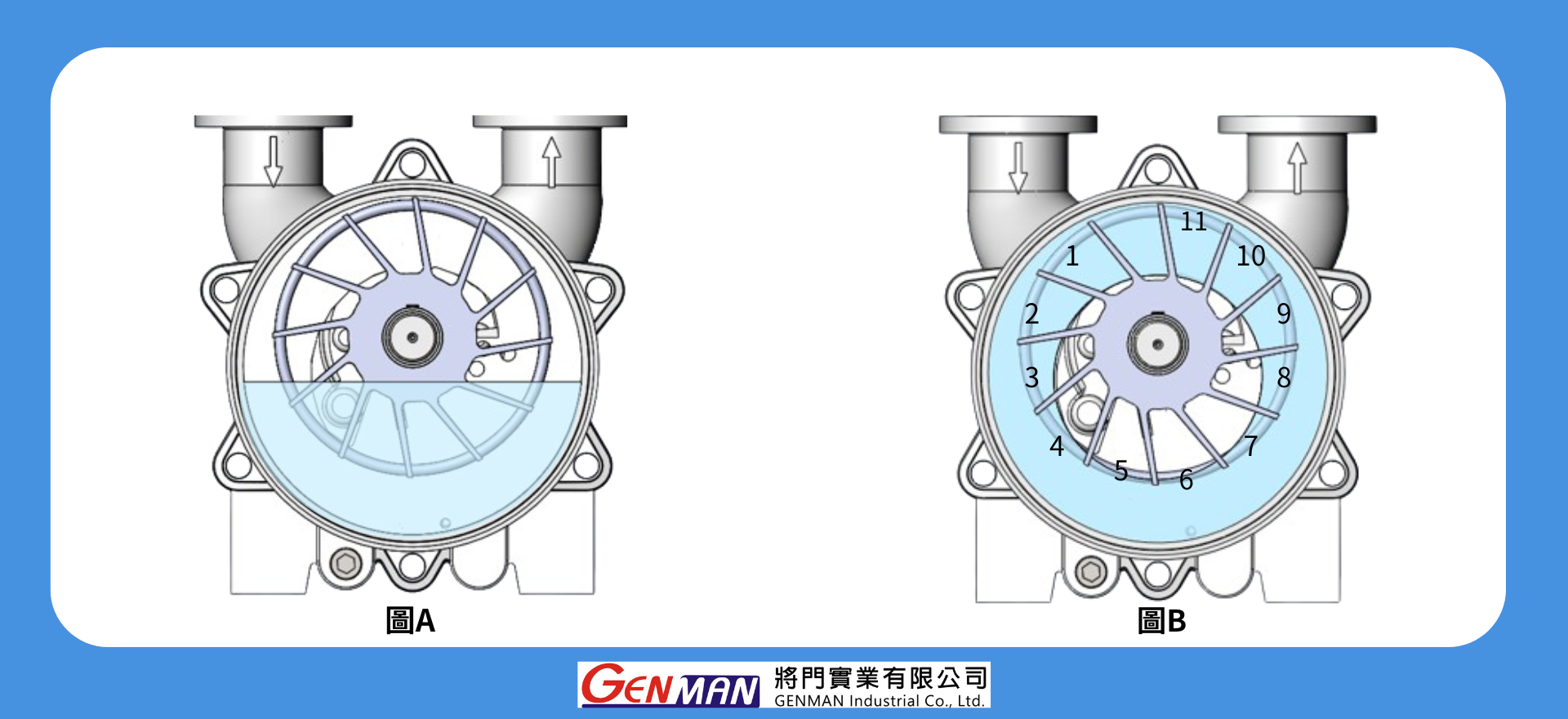

Liquid Ring Vacuum Pumps was designed based on liquid-seal piston principle. When an impeller is still, the fluid is flat (see Figure A). When an impeller is rotated, the fluid is thrown outward and forms a fluid ring with a center hollow. (see Figure B) The impeller is eccentricity compared to the machine body. When an impeller rotates from 1 to 5, the volume between two vanes gradually increases and begins to filling the gas. When an impeller rotates from 6 to 11, the filled gas retained between two vanes begins to emptying. Each rotation of impeller, the filling-and-emptying action thus creates a piston action.

●Single Stage Model Operation range:760 ~ 160Torr Ultimate vacuum:60Torr

●Two Stage Model Operation range:160 ~ 40Torr Ultimate vacuum:25Torr

GL SERIES LIQUID RING VACUUM PUMP

.L290*W136*H185mm

.Ultimate Vacuum:25Torr (-735mmHg)

Vacuum Chuck Purpose Vacuum Pump

‧Energy saving air-cooled designed.

‧100% Oil free discharge, no consumables replacement required, maintenance free.

‧System vacuum tank comes with large cleanable (detachable) observation window.

‧Compact design, mobile unit, easy installation, durable, low maintenance.